Batch Logic is BAD

Batch logic, or economic order quantity = EOQ, is the mathematical formula used by most planning systems. Yet this logic has THREE fundamental flaws.

It creates a different plan every time - no two plans are ever the same. This requires a lot of communication to let people know what the plan is this week. Humans are not very good at communicating - misunderstandings often occur.

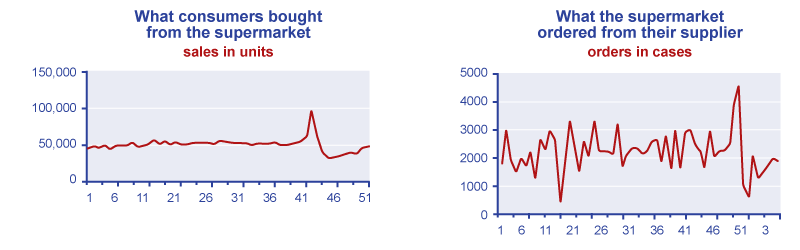

It creates what is usually referred to as the bull whip effect. Batch logic will round up the real demand to an "economic quantity". Fill the truck, trigger a bigger discount or fill the tank are all examples of this. At some point this rounding up will have to be rounded down as inventory will have gone too high.

This effect can be seen in the two graphs below.

After being issued the plan usually changes - WHY? If the underlying data changes then one gets a different answer = changes the plan. The calculation uses 3 key sources of data:

| 1. Sales forecast | Do you ever sell different to the forecast? |

| 2. Actual production outputs | Does production ever make more or less than the plan? |

| 3. Materials Inventories | Is there ever a difference between what the computer shows and the actual stock in the warehouse? |

It is normal for these three data sources to have inaccuracies. Of course you try to get the data accurate but for EOQ logic to work requires the data to be 100% accurate all the time.

This is NEVER going to happen - ever.

As long as the data has inaccuracies, the plan is guaranteed to change.

The importance of creating schedule stability through green stream RfS logic cannot be overstated - it drives customer service and Supply Chain inventory and cost improvements all at the same time

The importance of creating schedule stability through green stream RfS logic cannot be overstated - it drives customer service and Supply Chain inventory and cost improvements all at the same time